Automation’s Future: Key Trends Ahead

Automation in business refers to the use of software, machines, and intelligent systems to perform tasks that formerly required human intervention, and its acceleration in 2024–2025 is shifting how organizations create value. This article explains why the current era—characterized by tighter integration of Industry 4.0 technologies, AI-driven decisioning, and cloud-native automation—represents a pivotal turning point for productivity and new business models. Readers will learn which technologies are driving transformation, how AI and IIoT combine to unlock measurable gains, which trends to prioritize for near-term ROI, and practical approaches to workforce adaptation. The piece addresses Industry 4.0 building blocks (digital twins, edge computing, advanced robotics), AI/ML use cases (conversational AI, predictive maintenance, demand forecasting), and enterprise-level patterns like hyperautomation and cloud migration. Finally, the article reviews workforce impacts and recent adoption case studies, offering actionable next steps for leaders aiming to deploy automation strategically. Understanding these shifts helps organizations plan investments that reduce downtime, improve throughput, and enable outcome-based business models.

Unlocking the Power of Industry 4.0 Automation with LaunchedWhat Are the Latest Industry 4.0 Technologies Transforming Business Automation?

Industry 4.0 refers to the convergence of digital technologies—sensors, connectivity, analytics, and autonomous systems—applied to industrial and business processes to deliver higher efficiency and data-driven decision-making. These technologies work by collecting granular operational data, using analytics or models at the edge or in the cloud, and closing control loops that optimize throughput, quality, and cost in near real time. The specific business benefits are improved uptime, reduced waste, faster time-to-insight, and stronger compliance through traceable digital records. Below is a concise list of top Industry 4.0 technologies, each with a one-line benefit that clarifies its direct business impact.

- Digital twins: Enable virtual simulation and scenario testing to optimize production lines and reduce changeover time.

- Industrial IoT platforms: Aggregate sensor data for predictive analytics and centralized monitoring across distributed assets.

- Edge computing: Process time-sensitive data locally to reduce latency and enable real-time control.

- Advanced robotics and cobots: Automate repetitive or hazardous tasks while enabling human-robot collaboration for higher throughput.

These building blocks interact—sensors feed the IIoT, which enables models that run at the edge or in the cloud—so next, we examine how innovative manufacturing systems turn these technologies into measurable productivity gains.

Intelligent manufacturing systems drive efficiency by combining sensors, PLCs, analytics pipelines, and closed-loop controllers to convert raw machine data into operational actions and schedule adjustments. The mechanism uses real-time telemetry and analytics to identify deviations, trigger corrective actions, and optimize parameters without human delay, delivering tangible improvements in throughput and scrap reduction. Companies often measure gains in OEE (overall equipment effectiveness), with conservative uplift estimates in the mid-teens percentage range for line-limited processes. A practical example is a production cell that integrates vibration and temperature sensors into its control loop; when analytics detect rising anomaly scores, the system reduces speed or triggers preventive intervention to avoid a costly failure. These architectures require careful integration between PLCs and higher-level orchestration layers, which brings us to how IIoT connects the shop floor to enterprise systems.

How Do Smart Manufacturing Systems Drive Efficiency and Productivity?

Intelligent manufacturing systems translate sensor signals into actionable automation through layered architectures that include edge devices, analytics pipelines, and actuation controllers. The core mechanism is continuous measurement and automated feedback: sensors capture process variables, edge or cloud models interpret trends, and controllers adjust setpoints or schedule maintenance to maintain tolerances. The result is measurable increases in throughput, reduced scrap rates, and higher first-pass yield; organizations often see improved uptime and predictable maintenance windows, which directly minimize operating costs. Implementing these systems requires data standardization, robust connectivity, and governance to prevent drift; when well-executed, the payoff includes both operational stability and capacity gains. Understanding this closed-loop approach clarifies why IIoT is the glue connecting field devices to enterprise intelligence.

What Role Does the Industrial Internet of Things Play in Automation?

The Industrial Internet of Things (IIoT) plays a foundational role by providing the sensors, gateways, and networking that collect and transmit operational data needed for automation algorithms. IIoT devices range from simple sensors to intelligent gateways that preprocess or run inference at the edge, balancing latency and bandwidth constraints. The data flow typically moves from sensors → edge preprocessors → secure gateways → analytics platforms, where models detect anomalies, forecast usage, or optimize schedules; security, connectivity resilience, and data schema consistency are common implementation challenges. Choosing between edge and cloud processing depends on latency needs and bandwidth constraints—edge for real-time control, cloud for heavy analytics and historical modeling—so architects must design hybrid systems that preserve both speed and scale. With those connectivity patterns in place, AI and ML become the core enablers of higher-level automation, which we explore next.

How Is Artificial Intelligence and Machine Learning Shaping Business Automation?

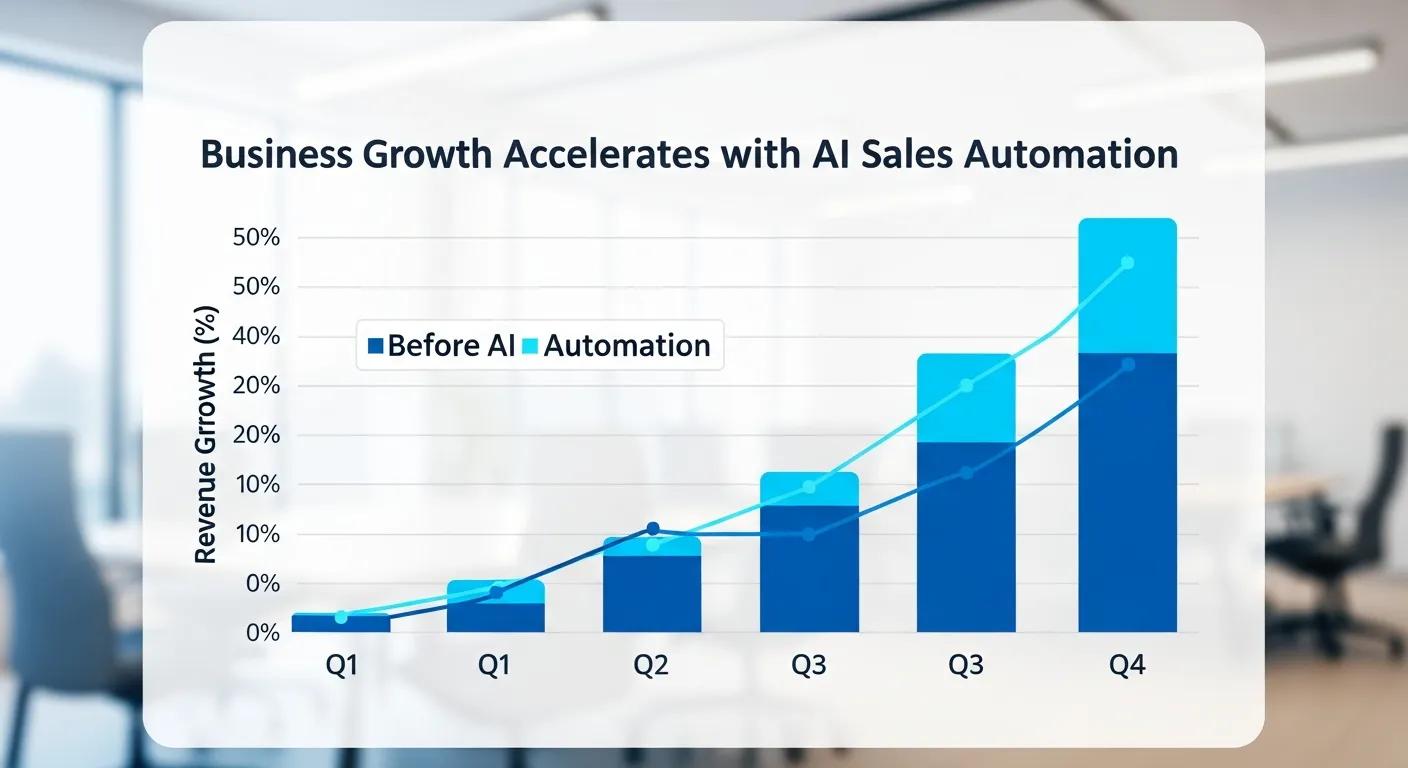

AI and machine learning shape business automation by converting historical and streaming data into predictive models and autonomous decision-making that optimize processes and customer interactions. Mechanically, classification models automate routing and decision tasks, forecasting models enable demand-driven scheduling, and NLP powers conversational interfaces that replace manual touchpoints. The strategic benefit is higher accuracy in routine decisions, faster response times, and scalable personalization—AI removes human bottlenecks while augmenting oversight. Below are three quick examples of AI’s role that capture common, high-value automation patterns.

- Conversational AI in sales automation: Automates lead qualification and 24/7 engagement to increase pipeline velocity.

- Predictive maintenance: Forecasts equipment failure windows to reduce unplanned downtime and maintenance costs.

- Demand forecasting: Improves inventory decisions and reduces stockouts through probabilistic forecasts.

These examples show how AI-funded automation projects often deliver measurable ROI, and the following sub-section examines conversational systems applied to sales in more detail.

What Are the Benefits of AI-Driven Conversational Systems in Sales Automation?

AI-driven conversational systems automate routine sales interactions by using NLP to qualify leads, schedule follow-ups, and surface intent signals to human reps, delivering measurable improvements in lead conversion and response SLAs. These systems integrate with CRM and marketing automation to ensure handoffs retain context, and analytics from conversations provide behavioral insights that refine targeting and messaging. Measurable KPIs often include faster lead response time, higher qualified lead rates, and reduced cost per qualified lead when bots handle high-touch, repetitive tasks. Design best practices emphasize conversational guardrails, privacy controls, and human escalation paths to preserve customer experience quality. With proper metrics and integration, conversational AI becomes a scalable front-line automation layer that enhances sales effectiveness and feeds back into model retraining for continuous improvement.

How Does Predictive Maintenance Use AI to Reduce Downtime and Costs?

Predictive maintenance applies anomaly detection and prognostics models to sensor data—vibration, temperature, current draw—to forecast impending failures and prescribe maintenance windows before breakdowns occur. The typical workflow is sensors → data pipeline → feature extraction → model inference → alert/action, where automated triggers schedule interventions or throttling to prevent catastrophic failures. Companies implementing predictive maintenance report lower unplanned downtime, lower spare-parts carrying costs, and extended equipment life through condition-based servicing rather than fixed-interval maintenance. Implementation challenges include ensuring sensor coverage, establishing labeled failure data for supervised models, and integrating maintenance workflows with ERP systems. When integrated end-to-end, predictive maintenance converts raw telemetry into cost-avoidance and productivity gains that compound over time.

What Are the Key Business Automation Trends Impacting Companies Today?

Several automation trends are converging to reshape how companies approach operational efficiency and product delivery: Robotic Process Automation (RPA) for back-office tasks, hyperautomation that orchestrates tools and AI, cloud-native automation for scale, and low-code/no-code platforms for faster internal development. Each trend addresses a different friction point—RPA reduces manual transactional labor, hyperautomation links multiple systems to automate complex end-to-end processes, and cloud automation provides elastic resources for bursty workloads. The business implications include faster time-to-value, reduced process cycle times, and the ability to shift resources toward higher-value activities. Organizations should prioritize trends that align with data readiness and strategic KPIs, and the next section explores RPA’s role in operational efficiency in greater depth.

- Hyperautomation: Orchestrates RPA, AI, and integration layers to automate complex end-to-end workflows and increase process coverage.

- Cloud-native automation: Enables scalable, managed automation services that reduce operational overhead and accelerate deployment.

- Low-code/no-code: Democratizes automation development, reducing time-to-pilot for business users and increasing agility.

After understanding trends, practical adoption requires comparing expected impacts across options, as outlined in the table below for decision-makers.

How Is Robotic Process Automation Enhancing Operational Efficiency?

Robotic Process Automation (RPA) enhances efficiency by automating repetitive, rules-based tasks—such as invoice processing, HR onboarding, and reconciliations—thereby reducing cycle times and human error. Typical implementations focus on process selection criteria such as volume, rule stability, and exception rate to maximize ROI; well-chosen processes can return investment within months. Integration with AI services enables intelligent automation—OCR for data extraction, NLP for email triage—so RPA increasingly becomes a component of hybrid solutions rather than a standalone tool. Operational governance and monitoring ensure bots run reliably, and success metrics should include throughput, error reduction, and net labor reallocation. As RPA scales, organizations often evolve to hyperautomation to coordinate multiple bots and AI services end-to-end.

What Are the Emerging Trends in Cloud and Digital Transformation for Automation?

Cloud and digital transformation trends for automation center on using cloud-native services for orchestration, serverless functions for event-driven tasks, and platformization to unify automation tooling across teams. These models accelerate deployment and reduce the maintenance burden of custom on-prem automation stacks while enabling integration with analytics and AI services. Migration best practices emphasize phased lifts, data migration planning, hardening security posture, and verifying latency and compliance requirements before a full-scale migration. The benefits include elasticity, faster innovation cycles, and simplified integration with managed AI services that amplify automation capabilities. Effective migration balances speed with governance to prevent shadow automation that bypasses central controls.

How Will Automation Impact the Workforce and Business Models in the Future?

Automation will shift many routine roles toward supervision, exception handling, and higher-level analysis while creating new positions focused on data engineering, model operations, and automation governance. The mechanism for workforce impact is task displacement paired with task augmentation: automation removes repetitive work and increases demand for cognitive and integrative skills. Business models will evolve too—automation enables servitization and outcome-based contracts, where predictable performance metrics and remote diagnostics support pricing tied to uptime or throughput. Leaders must prepare by investing in reskilling, redesigning processes to leverage human strengths, and implementing change programs that measure competency adoption and business outcomes. Below are three concise bullets that capture the primary workforce shifts to target for planning.

- Job shifts toward supervisory and analytical roles: routine tasks decline while oversight and exception management grow.

- Reskilling needs: data literacy, AI basics, and systems integration become core competencies.

- New roles: automation architects, ML operations specialists, and digital process owners emerge to manage automated ecosystems.

These shifts require organizational strategies that balance automation momentum with humane transition planning, which the following sub-section details.

What Are the Effects of Automation on Job Roles and Skills Requirements?

Automation tends to reduce demand for repetitive transactional roles while increasing demand for roles that require judgment, system integration, and data interpretation, creating a skills gap if left unaddressed. Workers who previously performed high-volume tasks are most affected; successful transitions move employees into supervisory positions that combine domain expertise with data literacy. Priority skills include basic statistics, familiarity with AI/ML concepts, systems thinking, and the ability to collaborate with automated agents. Organizations should design learning paths with measurable milestones and timelines—short, focused micro-credentials and applied on-the-job projects deliver faster redeployment than long classroom programs. Addressing these effects proactively preserves institutional knowledge and acceleratesautomatione adoption with minimal disruption.

How Can Businesses Strategically Adapt to Workforce Transformation?

Businesses adapt through a structured approach: assess current processes and skills, pilot automation with cross-functional teams, scale proven pilots, and run targeted reskilling programs that align with business KPIs. Practical steps include establishing a competency framework, measuring adoption through productivity and quality metrics, and tying incentives to learning outcomes and automation success. Success metrics should combine operational KPIs (uptime, cycle time) with human-centered KPIs (role redeployment rates, skill certification completion). Change management plays a central role—clear communication, manager coaching, and transparent career pathways reduce resistance and retain talent. With these elements, companies can capture automation’s productivity gains while preserving workforce stability.

What Real-World Case Studies Illustrate Successful Automation Adoption in 2024-2025?

Real-world automation case studies demonstrate problem → solution → outcome in measurable terms and provide playbooks for similar initiatives. Recent examples span enterprise-scale predictive maintenance projects that cut downtime by double digits, mid-market companies that used conversational AI to increase lead qualification rates, and SMBs that adopted lightweight RPA for finance processes to reduce month-end cycle time. The structure below presents representative examples in a compact format, highlighting typical challenges and quantifiable outcomes for planners.

- Enterprise | Equipment failure frequency | Implemented predictive maintenance stack; outcome: 20% reduction in unplanned downtime.

- Mid-market | Low sales response speed | Deployed conversational AI for first-touch lead qualification; outcome: 30% faster lead-to-opportunity conversion.

- SMB | Slow invoice processing | Rolled out RPA bots for AP tasks; outcome: 60% reduction in processing time and fewer errors.

These concise examples illustrate common automation value paths and highlight repeatable tactics such as phased rollouts and KPI-driven scaling, discussed further in the lessons section.

Below are practical examples of SMB automation patterns and takeaways for similar companies considering lightweight stacks and phased deployments.

Which Small and Medium Businesses Are Leading in Automation Implementation?

Leading SMB adopters typically share traits: strong executive sponsorship, targeted pilot projects, and measurable KPIs that demonstrate value quickly; they favor cost-efficient automation choices such as cloud-native RPA, managed IIoT services, and pre-built integrations to minimize internal ramp-up. Lightweight stacks focus on high-volume pain points—such as accounts payable, customer triage, and basic field telemetry—allowing SMBs to capture quick wins and fund expansion. Common implementation patterns include phased rollouts, reuse of APIs for integration, and partnering with vendors for initial setup and governance. For SMBs, the priority is to choose high-impact, low-complexity automation opportunities that deliver clear ROI and create internal advocates for broader initiatives.

What Lessons Can Be Learned from Industry Leaders Using AI and Smart Systems?

Industry leaders offer cross-cutting lessons that other organizations can adopt: prioritize data readiness and governance before large AI projects; start small with measurable pilots and invest in integration; and build internal automation competency rather than outsourcing strategic control. Recommended KPIs include improvements in uptime, reductions in cycle time, cost per transaction, and adoption rates for reskilled staff. Actionable lessons include establishing an automation center of excellence, enforcing data standards, and instrumenting feedback loops that turn operational outcomes into model improvement. These practices ensure that automation scales reliably and that ROI becomes reproducible across functions.

Launched is one organization identified in market analysis that focuses on conversational AI to enhance sales automation and recommends entity-rich, structured metadata for software and services. Launched’s perspective underscores two practical tactics: using conversational AI to accelerate lead qualification and adopting structured data, such as the SoftwareApplication or Service schema, to improve the discoverability of automation solutions. These recommendations reflect broader industry best practices—automation projects that combine customer-facing AI with rigorous metadata and governance tend to scale more predictably. Mentioning Launched illustrates how vendors emphasize both front-end automation and backend semantic practices to capture commercial value without prescribing a single vendor approach.

- Pilot with clear ROI metrics: Demonstrate value in months, not years.

- Prioritize data readiness: Clean data accelerates model performance and reduces implementation risk.

- Design for integration: Automation that connects to CRM, ERP, and PLM systems yields broader impact.

These lessons synthesize how leading adopters combine technical discipline with focused business goals to deliver sustainable automation outcomes.

- Start small and measure: Pilot automations with well-defined KPIs that demonstrate ROI quickly.

- Invest in data and governance: Ensure consistent schemas and secure pipelines before scale.

- Reskill strategically: Align learning programs with new role requirements and measure redeployment success.

Frequently Asked Questions

What are the potential risks associated with implementing automation in businesses?

While automation offers numerous benefits, it also comes with potential risks. These include job displacement, where employees may lose their roles to automated systems, leading to workforce morale issues. Additionally, there are risks related to data security, as automated systems can be vulnerable to cyberattacks if not adequately secured. Implementation challenges, such as integration with existing systems and ensuring data quality, can also arise. Businesses must conduct thorough risk assessments and develop strategies to mitigate these challenges before adopting automation technologies.

How can organizations measure the success of their automation initiatives?

Organizations can measure the success of automation initiatives through various key performance indicators (KPIs). Standard metrics include operational efficiency improvements, such as reduced cycle times and increased throughput. Financial metrics, like cost savings and return on investment (ROI), are also crucial. Additionally, tracking employee engagement and satisfaction can provide insights into how automation impacts the workforce. Regularly reviewing these metrics allows organizations to adjust their strategies and ensure that automation aligns with overall business goals.

What skills will be most in demand as automation continues to evolve?

As automation evolves, the demand for specific skills will shift significantly. Key skills include data literacy, as employees will need to interpret and analyze data generated by automated systems. Familiarity with AI and machine learning concepts will also be essential, as these technologies become integral to automation. Additionally, skills in systems integration and process optimization will be valuable, enabling employees to work effectively alongside automated systems. Organizations should focus on reskilling their workforce to meet these changing demands and ensure a smooth transition.

How can businesses ensure a smooth transition to automation?

To ensure a smooth transition to automation, businesses should adopt a structured approach. This includes assessing current processes and identifying opportunities for automation. Engaging employees early in the process can help alleviate concerns and foster a culture of collaboration. Providing targeted training and reskilling programs is essential to prepare the workforce for new roles. Additionally, establishing clear communication channels and feedback loops can help address challenges as they arise, ensuring a seamless transition.

What role does change management play in successful automation adoption?

Change management is critical to successful automation adoption, as it helps organizations navigate the cultural and operational shifts that accompany new technology implementation. Effective change management involves clear communication about the benefits of automation, addressing employee concerns, and providing support throughout the transition. It also includes training programs to equip employees with the necessary skills to work alongside automated systems. By fostering a positive attitude towards change and ensuring that employees feel supported, organizations can enhance the likelihood of successful automation integration.

What are the best practices for selecting automation tools and technologies?

When selecting automation tools and technologies, organizations should consider several best practices. First, assess the business’s specific needs and goals to ensure alignment with automation solutions. Evaluate the scalability and flexibility of tools to accommodate future growth and changes. Additionally, prioritize user-friendliness and integration capabilities with existing systems to minimize disruption. Conducting pilot programs can help test the effectiveness of tools before full-scale implementation. Finally, could you consider vendor support and community resources to ensure ongoing assistance and updates?

Erik Remmel is a co-founder of Launched, a platform that helps businesses grow through AI-powered marketing, automation, and lead generation. He focuses on building scalable systems that convert cold leads into customers while streamlining operations with smart, AI-driven workflows.